When it comes to selecting lighting products, up-front costs are just part of the picture. For the full story, we need to take a deeper look.

INTRODUCTION

When selecting lighting fixtures for commercial, industrial, or institutional projects, it’s common to focus solely on the sticker price. However, the true financial impact of a lighting solution is better understood by analyzing its Total Cost of Ownership (TCO)—a calculation that factors in not only the initial cost but also energy usage, maintenance, component reliability, and operational risks over the fixture’s lifetime.

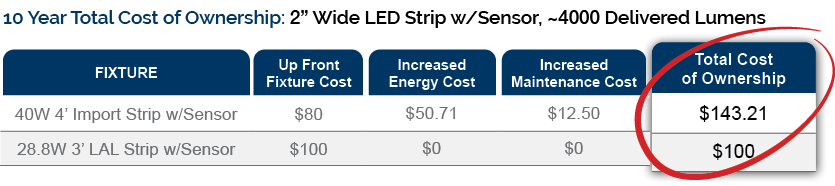

LA Lighting, a leading U.S. manufacturer based in El Monte, California, produces all its fixtures domestically using premium, top-tier components. In this article, LA Lighting will compare the 10-year TCO of one of its fixtures, the STW100 3’ 28.8W 4000 Lumen Strip, to an imported fixture from an undisclosed brand (referred to here as Brand C), the 4’ 40W 4000 Lumen Strip.

We’ll explore and quantify costs across three primary topics:

- Up-Front Fixture Cost

- Energy Cost Over 10 Years

- Maintenance and Component Failure Costs Over 10 Years

We’ll also explore other costs which can create significant premiums hidden in import fixtures without adding them to the final TCO. For helpful links, see the Appendix at the bottom of the page.

FIXTURE PRICE: UPFRONT COSTS VS. LONG-TERM VALUE

LA Lighting fixtures often come with a higher upfront cost when compared to imported alternatives. This is especially evident when not accounting for recent and upcoming tariff increases in 2025, which significantly impact the final price of imported goods.

The cost premium on LA Lighting fixtures is not primarily due to higher U.S. labor rates, as commonly assumed. Instead, it reflects the use of superior components:

- Name-brand, UL-listed LED drivers

- High-efficacy LED boards with solid metal cores

- Premium U.S.-sourced steel and plastics

- Advanced sensors and emergency battery systems

While imports may seem cheaper, the investment in quality components pays off in reliability and long-term savings.

FIXTURE SIZE AND DESIGN EFFICIENCY

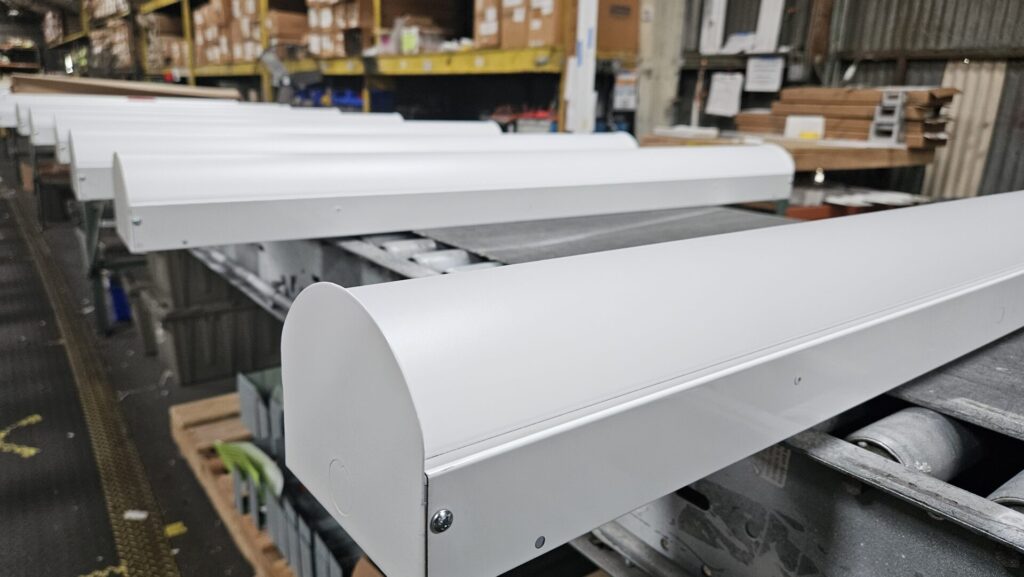

A major cost advantage of LA Lighting is its compact, high-output designs. Thanks to advanced LED boards and metal core technology, LA Lighting can achieve:

- 4000 lumens from a 3’ strip

- Up to 6000+ lumens from a 2’ or 3’ fixture

- Up to 50% higher efficiencies

By contrast, Brand C needs a 4’ fixture to achieve the same output. This not only increases material costs (steel, plastic, shipping) but also limits design flexibility.

ENERGY CONSUMPTION: SAVINGS THAT COMPOUND YEAR OVER YEAR

Energy efficiency is a defining feature of LA Lighting fixtures. While Brand C uses LEDs with a 105 lm/W output, LA Lighting delivers 135 lm/W—a 28% increase in delivered efficiency.

Power Consumption Details

- LA Lighting STW100: 28.8W (.028kW)

- Brand C Strip: 40W (.04kW)

- Delta: 11.2W (0.0112 kW)

Assuming 2000 annual operating hours, based on a facility with 4000 hours but using occupancy sensors to cut runtime by 50%, here are the annual savings:

10-Year Energy Cost Savings (@ $0.15/kWh):

Total 10-Year Energy Savings per Fixture: $50.71

These calculations do not include additional savings from LA Lighting’s high-performance occupancy sensors, which further reduce operating hours due to better detection and longer durability—often cutting usage by another 10–20%.

| Year | Annual Cost Savings |

|---|---|

| Year 1 | $4.03 |

| Year 2 | $4.23 |

| Year 3 | $4.45 |

| Year 4 | $4.67 |

| Year 5 | $4.90 |

| Year 6 | $5.15 |

| Year 7 | $5.40 |

| Year 8 | $5.67 |

| Year 9 | $5.96 |

| Year 10 | $6.25 |

MAINTENANCE AND COMPONENT QUALITY: RELIABILITY THAT PAYS OFF

One of the largest hidden costs in lighting systems is maintenance, especially when using low-cost, unreliable components common in imported fixtures. LA Lighting uses only UL-listed, name-brand components with 5-year minimum warranties.

Maintenance Cost Over 10 Years (Per Fixture)

- Driver Replacement: $25 part + $100 labor = $125 (10% failure rate) → $12.50 avg.

- Battery Replacement: $100 part + $100 labor = $200 (10% failure rate) → $20.00 avg.

Total 10-Year Maintenance Savings: $32.50 per fixture

Note: These values are conservative. Real-world data suggests import failure rates can exceed 30-50%, particularly for drivers and batteries. This value of $32.50 was also downgraded to $12.50 to show a conservative total value.

BUILD QUALITY: STEEL AND PLASTICS THAT LAST

Steel

Many fixtures claim to use “22Ga steel,” but imports often cut corners, using lower-grade or thinner steel. LA Lighting uses true-gauge U.S.-made steel, offering greater impact resistance, less deformation during maintenance, and better longevity under stress.

Plastics

Imported plastics frequently contain unregulated additives like styrene or recycled acrylics, which degrade over time. This leads to yellowing, brittleness, and cracking under minor pressure.

In contrast, LA Lighting uses virgin acrylic with DR (durability reinforcement) additives for a long-lasting finish that holds up over decades.

PROJECT RISK: DOWNTIME IS EXPENSIVE

Project rollouts involving overseas components introduce significant supply chain risks:

- Product discontinuation

- Delayed replacements

- Manufacturer shutdowns

These risks can easily create costly delays stemming from missed deadlines, fines, liquidated damages, and idle labor and rental equipment costs. While these aren’t included in the TCO calculation, they pose real-world financial risks.

CUSTOMIZABILITY: GET WHAT YOU NEED, NOT WHAT YOU’RE FORCED TO BUY

Imported lighting fixtures are mass-produced in a few standard models. If those don’t meet your needs, you’re out of luck.

LA Lighting offers true customizability:

- Custom lengths and widths

- Specific lumen packages

- Tailored drivers, LEDs and sensors

This means you can purchase a smaller, more cost-effective fixture that perfectly matches your application instead of overspending on stock options.

CONCLUSION

While imported fixtures may seem appealing at first glance, the Total Cost of Ownership tells a different story. With LA Lighting, customers benefit from:

- Superior efficiency and durability

- Lower maintenance and repair costs

- Customizability and risk reduction

- A reliable domestic supply chain

The upfront cost is an investment—one that pays dividends in performance, reliability, and long-term savings. So choose smarter. Choose American-made. Choose LA Lighting.